Researchers from the Chinese Academy of Sciences (CAS) have achieved a critical breakthrough in the core materials for solar cells, successfully developing a new generation of highly reliable silver paste. This advancement removes a major technical obstacle for the long-term stable operation of TOPCon (Tunnel Oxide Passivated Contact) cells.

TOPCon Cell Pain Point: The Reliability Challenge

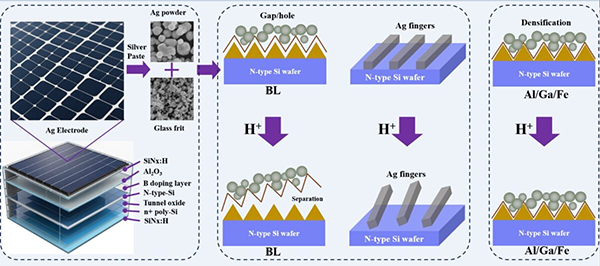

TOPCon technology, with its high-efficiency potential, has become a mainstream direction for the photovoltaic (PV) industry upgrade. However, a key step in its manufacturing process – Laser-Enhanced Contact Optimization (LECO) – poses a severe challenge to traditional silver pastes. The LECO process is performed after cell firing. It involves scanning a laser across the crystalline silicon cell while under reverse bias, promoting the formation of a Current-Fired Contact (CFC) structure between the metal electrode and the silicon substrate. This CFC structure offers superior conductivity and effectively eliminates contact resistance. However, this process places extremely high demands on the stability of the silver paste.

"An urgent improvement in the reliability of LECO-compatible silver pastes is required to ensure the stability of TOPCon solar cells," emphasized Dr. Jiangtao Di, the study's corresponding author, to pv magazine.

Image Source: Internet

Innovative Solution: Element Doping to Strengthen Glass Frits

To solve this challenge, the CAS research team innovatively introduced aluminum (Al), gallium (Ga), or iron (Fe) elements into the inorganic glass frits (glass powder) – a key component of the silver paste. This elemental doping strategy aims to optimize the formation process and chemical stability of the glass frits.

The researchers evaluated the performance of the new silver pastes through rigorous acetic acid degradation tests (simulating harsh environmental conditions):

1.Significantly Enhanced Corrosion Resistance: Silver pastes containing Al, Ga, or Fe performed far better in acetic acid corrosion environments compared to traditional pastes without these additives.

2.Substantial Reduction in Efficiency Loss: Dr. Jiang pointed out: “The efficiency loss of LECO-used silver paste with Al/Ga/Fe additives during acetic acid exposure can be less than 10%, and even as low as 5%. In contrast, without the introduction of these special elements, the degradation effect can markedly increase to over 50%."

Core Mechanism: Stabilizing Lead Oxide, Anchoring Electrodes

In-depth analysis revealed the fundamental reason for the performance improvement: the introduction of aluminum, gallium, or iron elements significantly enhanced the chemical stability of the lead oxide (PbO) component within the glass frits. This key enhancement ensures that the silver paste electrodes remain firmly anchored to the silicon cell surface even after exposure to harsh environments or long-term use, preventing contact failure and efficiency decline caused by corrosion or degradation.

Industry Significance: Paving the Way for TOPCon Scale-Up

"Our work offers highly reliable LECO-compatible silver pastes for TOPCon solar cells," concluded Dr. Jiang. This breakthrough research addresses a core material bottleneck concerning long-term reliability in the industrialization process of TOPCon cells, providing crucial material support for their large-scale application.

The related research findings have been published in the authoritative materials science journal Solar Energy Materials and Solar Cells, under the title "Strengthening TOPCon solar cell reliability via Al/Ga/Fe-added glass frits in LECO-compatible silver pastes against acid corrosion".

This innovative achievement by Chinese scientists marks a significant milestone in the localization and high-performance advancement of core PV auxiliary materials, injecting strong momentum into the global popularization and efficiency enhancement of TOPCon technology.