In the manufacturing process of solar silicon wafers, effectively reducing cutting loss has always been a core concern for the industry. Recently, a research team from a university conducted a systematic study on the kerf loss caused by lateral vibration during the diamond wire saw cutting process and proposed a quantitatively predictive model for kerf loss. This provides important theoretical support for optimizing cutting processes and improving wafer quality.

Image Source: Internet

Research Background and Challenges

"Kerf loss" refers to the wasted silicon material caused by saw wire wear and vibration during the process of cutting silicon ingots into wafers. As the photovoltaic industry continues to develop toward higher efficiency and lower costs, silicon wafers are evolving to become thinner and larger in size. However, the current mainstream diamond wire saw cutting technology often employs higher wire speeds and thinner wire diameters, along with increased wire spans, to improve efficiency. These factors collectively exacerbate lateral vibration of the wire during cutting, leading to uneven kerf width, increased thickness deviation of wafers, and even edge breakage.

The corresponding author of the study pointed out: "Lateral vibration not only directly increases kerf loss but also indirectly weakens the fracture strength of wafers, leading to higher breakage rates during cutting, cleaning, and transportation." Therefore, accurately predicting and controlling the additional kerf loss caused by lateral vibration is of great significance for advancing the cutting process of ultra-thin wafers.

Research Methods and Model Construction

The research team first established a dynamic model of the lateral vibration of the diamond wire under continuous excitation at both ends and conducted an in-depth analysis of the friction damping effect within the kerf. They used the finite difference method, commonly employed for solving differential equations, to numerically solve the model and validated the lateral vibration characteristics of the wire through measured data of vibration acceleration and displacement signals.

Additionally, the team leveraged Hertz contact theory—commonly used to describe the stress and deformation behavior when two non-conforming, elastic, and smooth objects come into contact—and combined it with the law of momentum conservation to further refine the predictive model for kerf loss.

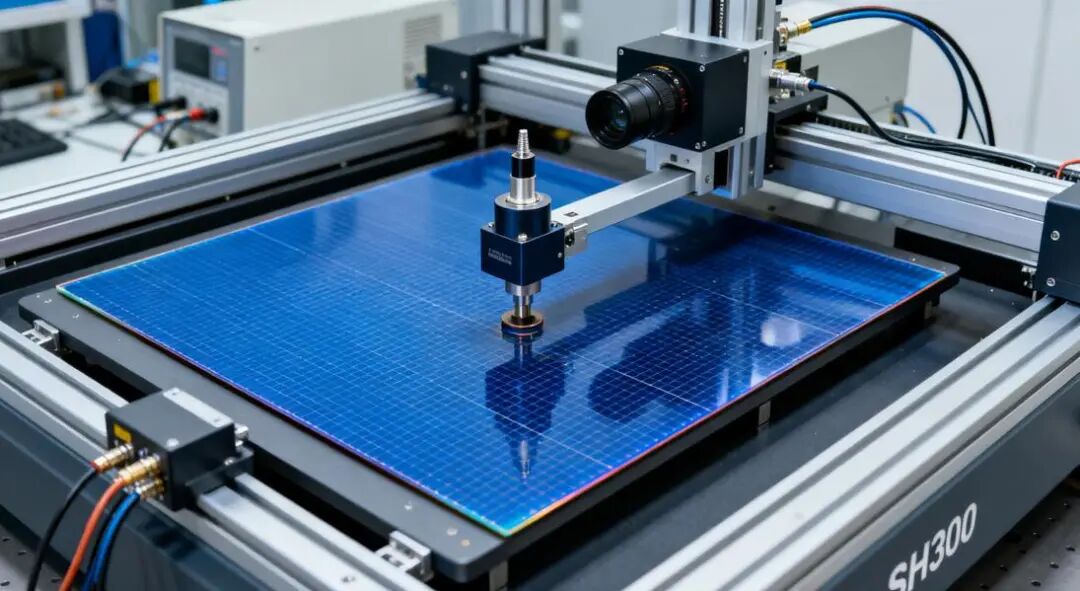

Image Source: Internet

Experimental Validation and Key Findings

To validate the model's effectiveness, the research team conducted three sets of cutting experiments using an SH300 machine tool provided by a company. The wire diameter used in the experiments was 350 μm, with a wire speed range of 1000–1400 m/min.

The results showed:

Kerf loss primarily originates from the vibration source signal during the main cutting stage, and this signal remains relatively stable;

Increasing wire tension or reducing wire span can effectively reduce kerf loss;

Increasing wire speed slightly increases kerf loss;

Under the same cutting parameters, smaller-sized wafers are more prone to larger kerf loss.

The researchers emphasized: "The greater the kerf loss, the worse the thickness uniformity of the wafers—and for photovoltaic monocrystalline silicon wafers, significant thickness deviation is unacceptable." Moreover, lateral vibration has a particularly significant impact on the edges of wafers, substantially increasing the risk of edge cracking.

Industrial Significance and Future Prospects

This study not only provides a method for predicting kerf loss but also offers a theoretical basis for optimizing cutting process parameters and developing new cutting equipment that suppresses vibration. The researchers stated: "The kerf loss model we proposed can predict the thickness uniformity of wafers, which will help better control the cutting quality of thinner wafers in the future and provide new perspectives for research on the fracture strength of photovoltaic wafers."

The research paper, titled "Prediction of excess kerf loss in diamond wire sawing based on vibration source signal measurement and processing," has been published in the academic journal Measurement. As the global solar industry continues to develop, advanced cutting technologies that effectively reduce material loss and improve wafer quality will play an increasingly critical role in the manufacturing of high-efficiency solar cells in the future.