Researchers at the École Polytechnique Fédérale de Lausanne (EPFL) in Switzerland have achieved a breakthrough in photovoltaic manufacturing. They have innovatively combined two critical high-temperature steps in TOPCon solar cell production into a single step, developing a novel "co-annealing" process. This technology not only simplifies the production flow but also significantly reduces manufacturing costs, offering a major boost to the photovoltaic industry.

Image Source: Internet

Pain Points of Traditional Process

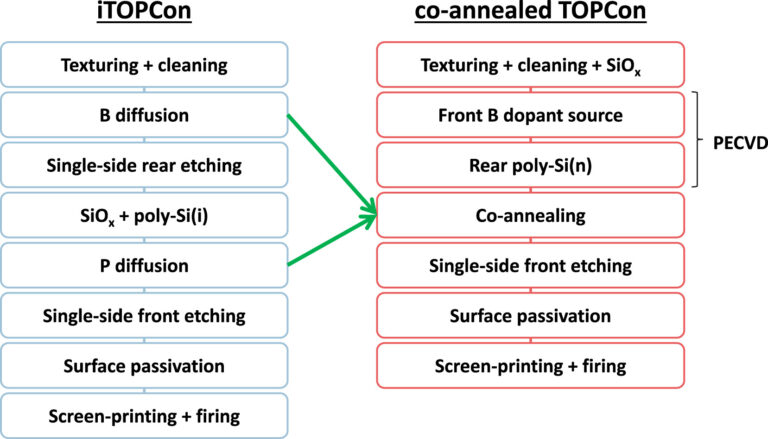

Requires two independent high-temperature steps: front emitter formation (depositing borosilicate glass layer - BSG) and back-side passivated contact preparation (high-temperature boron diffusion). This process is complex, energy-intensive, and requires significant equipment investment.

Innovative Solution

A revolutionary "co-annealing" process: After simultaneously depositing doped layers on both the front and back sides of the cell via Plasma-Enhanced Chemical Vapor Deposition (PECVD) technology, only one high-temperature treatment is needed to simultaneously activate both the front emitter formation and the back passivated contact.

Core Optimization - Oxygen Drive-in: The research team innovatively introduced an oxygen environment during the drive-in step of the co-anneal. Lead researcher Thibault Schaller emphasized: "This improvement is key to reducing emitter recombination losses and enhancing its compatibility with industrial metallization processes."

Image Source: Internet

Breakthroughs in Performance and Cost

Excellent Emitter Performance: The new process successfully produced a boron emitter with a surface concentration of 2.2×10¹⁹ cm⁻³ and a depth of 880 nm. These parameters are perfectly compatible with the industry-standard screen-printed silver/aluminum paste firing metallization processes.

Significant Cost Reduction Potential: Reducing the number of process steps directly lowers equipment investment, energy consumption, and production time. Schaller specifically noted that this technology is particularly significant for countries and regions with high factory equipment costs, as it has the potential to shorten the energy payback time.

Clear Efficiency Target: The team aims to achieve proof-of-concept co-annealed TOPCon cells exceeding 24% conversion efficiency in the laboratory environment.

Challenges and Prospects

The current research also identified non-uniform passivation quality after co-annealing, requiring further optimization. However, the process has already demonstrated strong potential regarding boron concentration profiles, passivation quality, and contact resistivity.

As an upgrade path for PERC technology, TOPCon is widely regarded as the next-generation mainstream PV technology due to its higher theoretical efficiency limit (approaching 29%) and good compatibility with existing production lines. EPFL's process innovation directly addresses the key manufacturing cost pain point of TOPCon, potentially accelerating its industrialization and replacement process.

This research, published in the top-tier photovoltaic journal Solar Energy Materials and Solar Cells, marks a crucial step forward for TOPCon cells towards higher efficiency and lower cost. With continued process refinement, the streamlined and efficient "co-annealing" technology has the potential to reshape the manufacturing landscape of next-generation high-efficiency solar cells, accelerating the widespread adoption of photovoltaic power generation.