Amidst the wave of transition from Industry 4.0 to Industry 5.0, Korean scientists have infused "smart capabilities" into solar cell manufacturing. A research team from Korea University has successfully developed an innovative methodology that utilizes machine learning to accurately predict and optimize key process parameters, significantly enhancing the efficiency and precision of photovoltaic cell production.

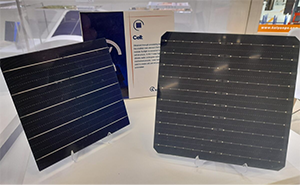

Image Source: Internet

Industrial-Grade Data-Driven Model

Moving beyond traditional lab-simulated data, the research team collected 3,420 sets of detailed data from equipment highly simulating actual industrial production lines. This data encompassed 10 core variables in the phosphorus oxychloride (POCl3) doping process: Pre-deposition temperature and time, Drive-in temperature and time, Process gas parameters (POCl3 flow rate, O2 flow rate, chamber pressure) , Wafer position information (wafer boat position, slot number, wafer position), etc.

"Smart Brain" for Precise Prediction and Optimization

Based on this extensive industrial dataset, the team built a powerful machine learning model:

Accurate Prediction: The model can accurately predict the key final product metric – sheet resistance – based on complex input process conditions.

In-Depth Analysis: Using the game theory-based SHAP (SHapley Additive exPlanations) method, the model clearly reveals the influence weight and direction of each process variable on the sheet resistance prediction, granting the model "interpretability."

Autonomous Optimization: Combined with the Bayesian optimization algorithm, the model can inversely deduce the optimal combination of process parameters to achieve the target sheet resistance (e.g., 150 Ω/sq). This process required only 200 effective trials (100 initial random sampling + 100 Bayesian optimization trials), far lower than the cost of conventional and expensive trial-and-error methods used in the industry.

Image Source: Internet

A Reliable Cornerstone Towards Industry 5.0

Research lead Seungtae Lee emphasized the universal value of their work: "Our core objective is to propose a methodology for deeply integrating machine learning into actual industrial processes. The model's learned results and predictions align with established physical and theoretical understanding, providing solid assurance of the model's reliability and interpretability in real manufacturing environments."

Described in the study "Bayesian-optimization-based approach for sheet-resistance control in silicon wafers toward automated solar-cell manufacturing" published in Materials Science in Semiconductor Processing, this research not only provides a clear pathway for the photovoltaic industry towards efficient and intelligent production, but its groundbreaking methodological framework also holds the potential for extension to various complex industrial processes. It serves as a key cornerstone for accelerating the progress of Industry 4.0 and paving the way for Industry 5.0.

As artificial intelligence deeply integrates into the core aspects of manufacturing, the smart factory model, driven by data and centered on model-based decision-making, is reshaping industrial competitiveness. The successful practice of Korean scientists in the field of solar cell manufacturing provides an invaluable template for the intelligent upgrading of global manufacturing.