Researchers at Delft University of Technology (TU Delft) in the Netherlands have recently made significant progress in heterojunction solar cell technology. By employing an innovative "top-down" processing method, they successfully designed a rear junction heterojunction solar cell (RJ-SHJ) with a localized front contact architecture, achieving a conversion efficiency of 23.4%. This breakthrough not only improves the cell’s fill factor (FF) but also significantly enhances its resistance to ultraviolet-induced degradation, paving the way for the commercialization of next-generation high-efficiency solar technologies.

Image source: Media news_Photovoltaic cell production

Technical Breakthrough: Self-Aligned Localized Contact Architecture

The core innovation lies in the development of a self-aligned method to precisely position the cell’s front contact electrodes. Traditional heterojunction cells typically require a transparent conductive oxide (TCO) layer covering the entire front surface for charge transport, but this design can lead to optical absorption losses and increased resistance.

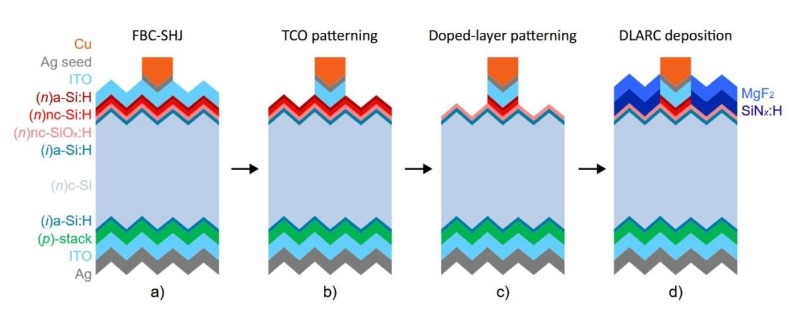

The technical structure provided by the research team

“Our approach uses localized etching to retain the front contact layer only in areas covered by the metal grid, while completely removing it elsewhere,” explained Dr. Sebastian Smits, the lead researcher, in an interview with pv magazine. This process leverages the metal grid as a mask to selectively etch away the TCO layer and n-doped layers in non-contact regions, avoiding damage to the cell’s mechanical stability.

Key Process: Nanocrystalline Silicon Oxide "Barrier" Layer

To achieve high-precision control over localized contacts, the team introduced an 8-nanometer-thick hydrogenated nanocrystalline silicon oxide (nc-SiOx:H) layer between the intrinsic layer (i-layer) and the contact stack. This ultrathin layer acts as a “barrier” during etching, protecting the underlying intrinsic layer from damage while minimizing resistive losses in the contact layer.

“The nc-SiOx:H layer maintains surface passivation (preventing carrier recombination) and avoids reductions in fill factor or open-circuit voltage caused by etching,” emphasized Smits. Additionally, the retained TCO layer in the window area continues to function as an anti-reflective coating (ARC), reducing optical losses caused by the refractive index mismatch between silicon and air.

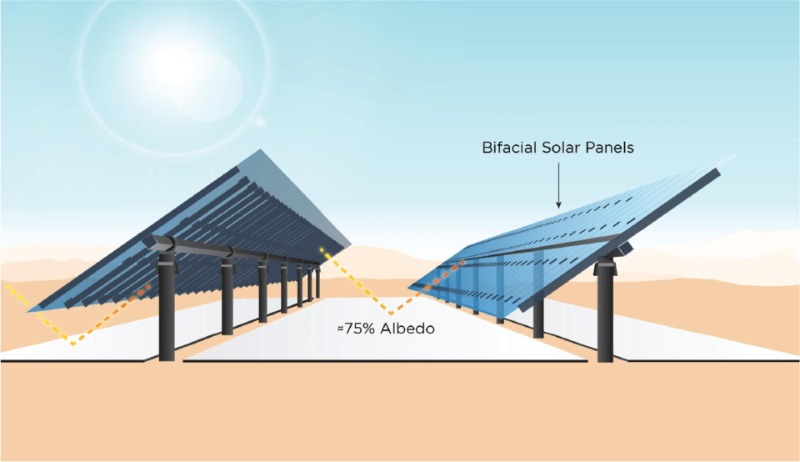

Image source: Media news_The power generation efficiency of bifacial photovoltaic modules is affected by refraction

Performance Advantages and Potential Applications

Enhanced Efficiency and Stability

The localized contact design significantly improves the fill factor and reduces UV-induced degradation rates, directly enhancing the cell’s long-term reliability in outdoor environments.

Process Compatibility

The technology is compatible with existing heterojunction production lines, requiring no complex masks or additional equipment—only an added etching step in standard workflows—thus lowering mass-production costs.

Versatile Applications

The architecture is particularly suited for bifacial modules or high-light-utilization scenarios, as its highly transparent window area maximizes absorption of rear-side incident light.

The research team plans to further optimize the material composition of the contact layers and etching processes, aiming to push cell efficiency beyond 24%. They are also exploring applications of this technology in perovskite/silicon tandem cells to surpass the efficiency limits of single-junction cells.

This achievement has been published in top international energy journals and has garnered significant industry attention. As the clean energy transition accelerates, such high-efficiency, low-cost solar technologies are expected to drive further reductions in photovoltaic costs within the next five years.

TU Delft’s research reaffirms that traditional silicon-based solar cells still hold vast potential for performance improvements through innovative structural and process design. This technology not only injects new momentum into the industrialization of heterojunction cells but also provides critical technical reserves for global carbon neutrality goals.

Image source: Media news_TU Delft clean-room