PV Panel Manufacturers Drive Global Solar Innovation with Cutting-Edge Technologies

As the world races to achieve net-zero emissions, PV panel manufacturers are emerging as pivotal players in the green energy revolution. From breakthrough efficiency records to sustainable manufacturing practices, these companies are reshaping solar power’s role in the global energy mix. Here’s how they’re making a difference:

1. Breaking Efficiency Barriers with Next-Gen Technologies

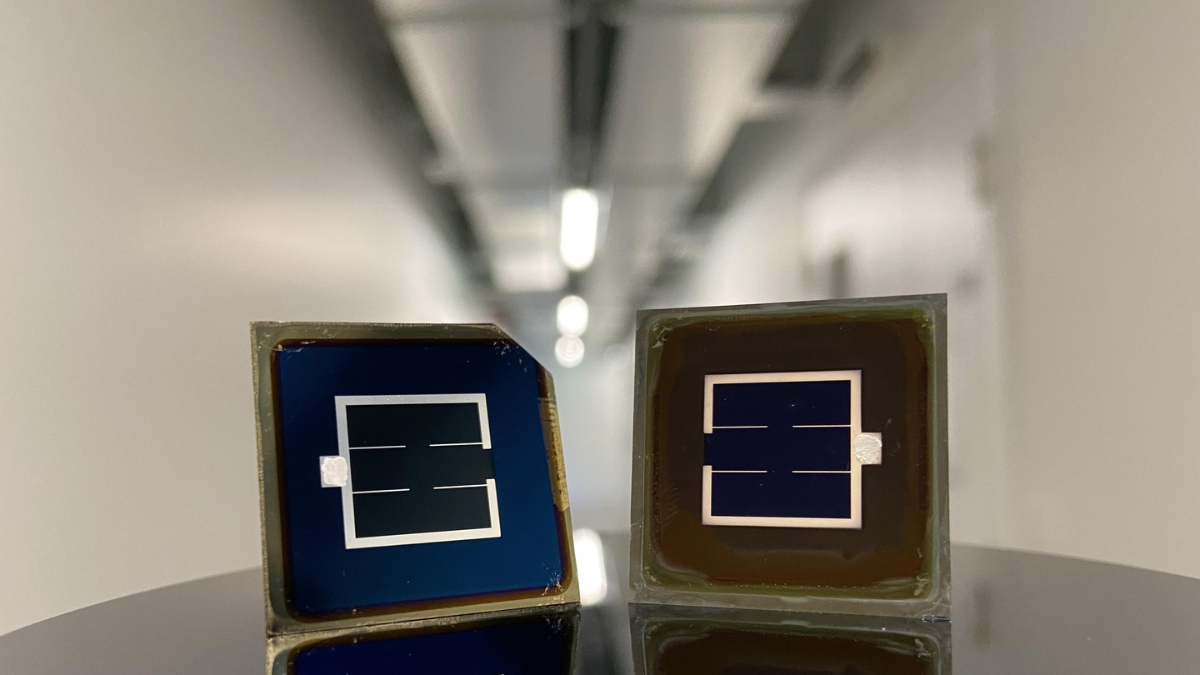

PV panel manufacturers are pushing the limits of solar efficiency. Oxford PV, a leader in perovskite tandem solar technology, recently announced its panels achieved a record 25% conversion efficiency, surpassing traditional silicon-based modules. Even more impressively, their panels lost only 1% efficiency after a year of real-world testing—a critical milestone for durability. Meanwhile, Trinasolar unveiled its i-TOPCon Ultra modules at the 2025 Green Energy Expo in Korea, boasting a lab cell efficiency of 26.58% and power outputs up to 740W, tailored for harsh climates like Korea’s extreme winters.

Image source: News media

These advancements are not confined to labs. Huasun Energy, named one of TIME’s Top GreenTech Companies of 2025, has commercialized heterojunction (HJT) solar modules with a carbon footprint of 366.12 g CO₂ eq/W—far below industry averages—while pioneering HJT-perovskite tandem cells for even greater efficiency gains.

Image source: News media_ perovskite - silicon tandem cells

2. Scaling Sustainable Manufacturing

Sustainability is no longer optional. ES Foundry, America’s largest PV cell factory, exemplifies this shift. Located in South Carolina, the facility sources all chemicals and gases domestically and employs 500 workers, with plans to reach 3 GW annual capacity by late 2025. By prioritizing U.S.-made components, ES Foundry helps manufacturers leverage tax credits under the Inflation Reduction Act.

Image source: News media_ES Foundry’s factory

In Asia, JinkoSolar’s BIPV (building-integrated photovoltaics) projects, like Dubai’s zero-carbon DEWA headquarters, highlight how PV panel manufacturers integrate solar into urban infrastructure. The project reduces 145,000 tons of CO₂ emissions over 25 years, aligning with JinkoSolar’s ESG commitments, including 100% renewable energy at three global factories.

Image source: News media_Dubai’s zero-carbon DEWA headquarters

3. Expanding Applications: Floating Solar and Smart Solutions

Innovation extends beyond rooftops. Singapore’s 60 MW floating solar farm—spanning 45 soccer fields—powers five water treatment plants, cutting emissions equivalent to removing 7,000 cars from roads. The project’s water-cooled panels outperform rooftop systems by 5–15%, proving solar’s adaptability.

Image source: News media_Singapore’s floating solar farm on a reservoir

Chinese manufacturer Fonrich is revolutionizing safety with its MLPE (Module-Level Power Electronics) solutions. Their integrated smart panels feature rapid shutdown mechanisms and real-time monitoring, reducing fire risks and installation costs by 25%. Such innovations are critical as PV panel manufacturers target diverse markets, from residential rooftops to industrial complexes.

4. Global Collaboration for a Greener Future

The industry’s growth relies on cross-border partnerships. Trinasolar’s collaboration with TÜV Rheinland ensures its modules withstand extreme conditions, from -43°C temperatures to hurricane-force winds. Similarly, Taiwan’s Sinpro Energy partnered with German certifiers to launch steel-integrated BIPV roofing panels, merging structural durability with energy generation.

PV panel manufacturers are not just meeting today’s energy demands—they’re redefining what’s possible. With advancements in efficiency, sustainability, and application diversity, solar power is poised to dominate the renewable transition. As Alex Zhu, CEO of ES Foundry, notes, “Domestic manufacturing isn’t just about competitiveness; it’s about securing a cleaner future for all”.